You are here: / Home

Helium extraction from natural gas

EuroNorm GmbH, Federal Ministry for Economic Affairs and Energy

Dr. Erik Neuber

+49-351-4081-5122

Innovative solutions for helium extraction

Separation of high purity helium from natural gas with very low helium concentrations

Helium is a very valuable noble gas with numerous applications in different fields of industry and research. Liquid helium is for example indispensable as a refrigerant in cryogenic systems such as magnetic resonance imaging. On Earth, the most important natural helium occurrences are found in the atmosphere and in natural gas. Because of its low concentration in air – only approx. 0.0005% – helium is recovered primarily from natural gas. However, in recent years an extreme worldwide helium shortage emerged, which has manifested itself in acute supply shortages and in large price increases. Therefore, new approaches and innovative processes for helium recovery from natural gas were examined within this research project at the ILK Dresden. In particular, these methods will be applicable to extract efficiently high purity helium from natural gas sources even with very low helium concentrations.

The main aim of the R&D project was to analyze different processes that can be used in the future as a possible technology of helium extraction plants. Such a plant could be used in the natural gas industry, either in close proximity to a natural gas source or away from the source connected to a gas pipeline.

Within this project a technological process of He extraction from natural gas divided into the following steps has been developed:

- Development and research of the vortex tubes;

- Analysis of the membrane separation technology for the helium recovery process;

- Investigation of the condensation and adsorption stage;

- Entire process modeling.

A simplified scheme in Figure 1 shows the process combination. The starting point is raw natural gas with a He content of less than 0.5 vol. %. The main component of the raw natural gas is methane, other components are nitrogen, higher hydrocarbons and small amounts of hydrogen and various noble gases.

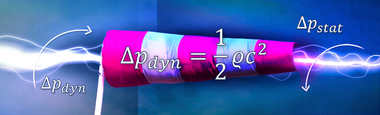

Since natural gas can contain CO2 and ice which must be avoided in the subsequent low-temperature membrane process, thus, the first process step consists of the separation of CO2 by the combination of specially developed vortex tubes used in the condensation process.

The next step in the helium enrichment process is carried out by a membrane process that consists of five membrane stages. During this process, mainly methane and nitrogen are separated from the helium and so the helium is enriched to a purity from 0.5 vol. % up to about 97 vol. %. Low-temperature membrane separation was also studied within this project.

The last step in the process is the condensation and adsorption of the remaining CO2, N2 and CxHx traces from helium flow. The subsequent final step consists of the freezing out of low boiling impurities such as water and CO2, and adsorption of residual impure components for obtaining high purity helium with a purity of more than 99.999 %.

Thus, the technological processes in the field of membrane technology, low-temperature membrane gas separation, vortex tube, and condensation/adsorption have been investigated both theoretically and experimentally in this R&D project.

Further Projects

Optimizing HVAC operation with machine learning

Intelligent control of HVAC systems – high comfort with low energy demand

Industry 4.0 membrane heat and mass exchanger (i-MWÜ4.0)

Linking the entire life cycle of a multi-functional air handling unit