You are here: / Home

Innovative cryogenic cooling system for the recondensation / liquefaction of technical gases up to 77 K

high performance efficiency, environmental friendliness, compactness, cost-effectiveness

The main objective of the R&D project is the development of a cryogenic cooling system capable of recondensing a gas stream of vaporized natural gas back to its liquid form or cooling and/or liquefying other gases to a temperature level of 77 K. The technical solutions for the development of the system aim to provide a number of advantages over existing systems: high performance efficiency, environmental friendliness, compactness, and cost-effectiveness.

The cryogenic refrigeration system will include several innovations and technical solutions:

- Development of an innovative and cost-effective refrigeration source based on a mixed-refrigerant low-temperature cooler.

- Detailed calculation and determination of innovative as well as adapted zeotropic refrigerant mixtures, which optimize the energy efficiency of the cooler with respect to its application and ensure environmental friendliness.

- Determination of the optimal as well as adapted working parameters and dimensions of the cooler and its components with regard to its desired properties (efficiency, fire protection, etc.).

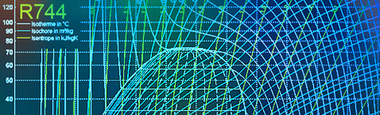

On the basis of the chosen principle of the cryogenic cooling system, a special Linde-Hampson refrigerant mixture cooler was designed, which works with zeotropic refrigerant mixtures and should achieve temperatures of ≤ 100 K, see Figure 1. Thermodynamic calculations of the circuit and the determination of the components of the working mixture and their composition were carried out. For this purpose multiparametric optimization methods as well as gradient methods with different calculation grids were used.

As functional model, a system was implemented which should enable the liquefaction of nitrogen via a second refrigerant circuit. This model was initially tested with simple standard refrigerants and multi-component refrigerant mixtures and works very reliably. The results obtained will be used in the next step to demonstrate the liquefaction of nitrogen.

Your Request

Further Projects

Verification of storage suitability of cryo tubes

Artificial aging of primary packaging for biobanking applications