You are here: / Home

Micro fluidic expansion valve

PTJ (03ET1207A)

Dipl.-Ing. Sandra Tippmann

+49-351-4081-5131

Hahn-Schickard-Gesellschaft für angewandte Forschung e.V., Liebherr-Hausgeräte Ochsenhausen GmbH

for increasing of the efficiency of small and compact cooling units

Since the first household refrigerators and freezers were developed in the 1920s, the refrigerant has been expanded via a thin, meter-long capillary tube as a throttle (throttle capillary). Adjustable valves instead of the capillary tube, which enable precise adjustment of the cooling capacity, so-called expansion valves, have so far been reserved only for larger cooling systems due to the technical challenge with small cooling capacities.

The aim of this joint project was the development and analysis of an adjustable, energy and cost efficient microfluidic expansion valve on the basis of microsystems technologies for the use in small cooling units with a cooling capacity from 30 to 200 W. Thereby especially

- the power consumption and

- the necessary manufacturing resources have to be reduced.

- At the same time advantages in the handling comfort for end-users and

- the cost structure have to be reached.

To achieve these objectives, microfluidic principles and technologies, as well as microsystems design and mounting technologies were used. This contained the selection of appropriate materials including the proof of its stability and durability to the occurring refrigerant-oil-mixtures. Furthermore, a control concept has been deflected and adapted to the properties of the micro expansion valve.

In this joint project, the first electronic micro-expansion valve was developed, which was specially adapted to the small cooling capacities of household refrigerators and freezers (approx. 30-200 W). The integration of functional patterns in conventional household refrigerators and freezers has shown that energy savings of approx. 4% compared to a throttle capillary can be achieved. On the 72 million household refrigerators and freezers available in Germany, this corresponds to an estimated electricity saving potential of 400,000 MWh per year or the annual electricity consumption of 250,000 people.

Further Projects

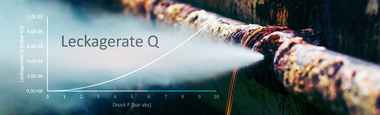

Investigation according to DIN EN ISO 14903

These tests according to DIN EN ISO 14903 are possible at ILK Dresden