You are here: / Home

Performance tests of refrigerant compressors

Does your compressor perform well?

The Test center PWLP supports the industry in the development of environmentally friendly, energy-efficient vapor-compression refrigeration system and compression heat pumps. In practice, the F-Gas Regulation EU 517/2014 means the increased use of flammable refrigerants (KM) of classes A2 and A3.

The ILK Dresden offers the following services for you:

Investigation of compressor parameters

For a defined application map of open, semi-hermetic or hermetic respectively one or two stage refrigerant compressors we determine the refrigerating capacity, power absorbed, COP, volumetric and isentropic efficiency.

For a defined application map, we determine according to the standards

DIN EN 13771-1 and DIN EN 12900 the

Cooling capacity, drive power, COP, delivery and quality level

Now also for flammable refrigerants like propane!

We determine the parameters for

- one- or two-stage (with integrated ECONOMISER),

- semi-hermetic or

- hermetic compressors

- types: reciprocating or rolling piston, scroll compressors

The ASEREP property library from ASERCOM is the source of the refrigerant property values

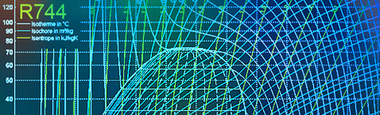

| Displacement [m³/h] | Refrigerating capacity [kW] | Refrigerants |

| 50..200 | ...200 | A1: R134a, R1234yf, R404A, R407A, R407C, R407F, R448A, R513A, R152a, R452A, etc. |

| 3...30 | ...25 | A2L/A2: R452B, R32, R1234yf, R1234ze |

| 3...30 | ...25 | A3: R290 (Propane) |

Current calibrations of the measuring systems are a matter of course.

Within the scope of our flexible accreditation, further measuring tasks can be realized according to applicable test standards.

Compressor service life study

We test the thermal / mechanical long-term behavior and the interaction between compressor, refrigerant (A1, A2 / L and A3) and oil

in the LifeTimeTest LTT500

- according to the individual requirement of the customer or

- according to our ILK standard procedure over approx. 500 h:

- with defined variable loads in the compressors operating map (stress level 1… 6)

- when the permissible operating parameters are exceeded (on / off cycles, reduced overheating, oscillation, liquid) and with analysis of the development over time of the compressor parameters at the reference point (according to DIN EN 13771-1).

Examination of the compressor and oil condition

We check in a condition analysis of the compressor

- possible damage from field use or after completing a LifeTimeTest LTT500

- based on macroscopic mechanical wear characteristics, electrical properties of the electric motor and oil condition

- optionally with technical evaluation of the compressor according to Guideline VDI 2225 (objectification of characteristics without directly measurable comparison parameters).

Forschung und Entwicklung

Das ILK Dresden ist seit vielen Jahren auf dem Gebiet der Entwicklung und Prüfung von Kälte- und Wärmepumpentechnik tätig. Die Entwicklungsarbeit wird individuell und in enger Zusammenarbeit mit dem Auftraggeber geleistet.

Das ILK Dresden besitzt ein langjähriges Know-how in der Untersuchung von Kältemittelverdichtern. Das notwendige Know-how für die Bewertung der Maschinen wurde insbesondere in den Förderprojekten erarbeitet:

- "Energieeffizienz von Kältemittelverdichtern", (BMWi EN FKZ IW073034),

- "Mehrfach-Zwischeneinspritzung an Rollkolbenverdichtern", (BMWi EN FKZ VF120022),

- "Prüfstand und Prüfverfahren für Verflüssigungssätze" (BMWi EN FKZ MF150072)

- "Verfahren für Verdichterschutz", (BMWi EN FKZ MF150165).

In diesen Projekten wurden insbesondere Erkenntnisse zu folgenden Themen gewonnen, die eine fachgerechte Interpretation der Ergebnisse ermöglichen:

- konstruktiver Aufbau unterschiedlicher Verdichterkonstruktionen

- Verläufe von Gütegrad und Liefergrad als Funktion von Verdichterbauart und Kennfeld

- Leistungsmessverfahren mit reduzierter Messunsicherheit an Verdichtern unterschiedlicher Bauarten

- Entwicklung von Kälteleistung, Antriebsleistung und COP in Abhängigkeit von Bauart und Einsatzbedingungen

- Verhältnisse von äußeren und inneren Bedingungen des Verdichtungsprozesses und Auswirkungen auf die Definition von vergleichenden Kennwerten

- Verfahren zur Bestimmung des Ölanteils im Kältemittelmassenstrom

Your Request

Further Projects

Electrochemical decontamination of electrically conducting surfaces „EDeKo II“

Improvement of sanitary prevention by electrochemical decontamination