You are here: / Home

Thermal engines

Power Generation from Waste Heat

Principally every refrigeration process could also work as a power cycle. In this way an energy consuming machine which provides a temperature below the ambient temperature turns into a heat engine operating between the ambient and a higher temperature. In a first step cryogenic refrigeration cycles are used reversely as heat engines, as they can handle large temperature gradients.

Thermal engines similar to the Stirling cycles

In cooperation with FOX exhaust systems, the ILK Dresden has developed a waste heat recovery system. The thermal engine dedicated for the car exhaust gas system was now presented at the International Motor Show (IAA, 2011) in Frankfurt for the first time.

With the aid of a model the functionality was demonstrated impressively.

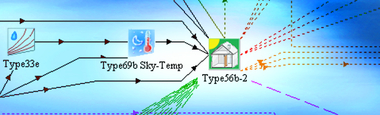

The prototype will deliver an electrical power of 2 kW, at an exhaust gas temperature between 300 and 500°C (570 to 930°F). Currently optimization work, mainly related to generator, is underway. The figure below shows the illustration of the thermal engine in an exhaust tract.

Thermal engines related to other thermodynamic cycles

With several industrial partners heat engines are under development, which operate according to the following thermodynamic cycles:

- closed and open Joule process

- valve less Ericsson process

Further Projects

Low noise and non metallic liquid-helium cryostat

Low-noise Magnetic Field Cryostat for SQUID-Applications

Cryostats, Non-Metallic and Metallic

position indenpendent, highest endurance, tiltable for liquid helium and liquid nitrogen

Cryogenic liquid piston pumps for cold liquefied gases like LIN, LOX, LHe, LH2, LNG, LAr

Feeding pumps for cryogenic liquid gases