You are here: Home / Measurements and Tests

Service offer for Leak Detection and Tightness Test

Use our experience

Service offer for leak detection and tightness test

Leak detection and tightness tests are interesting for many areas of technology, e.g. vacuum technology, refrigeration and construction of chemical plants, reservoir plants, power stations or tanks. Depending on the task we offer:

- Development of tightness test technologies (according to DIN EN 1779, DIN EN 13185)

- Coarse leak detection: vacuum pressure rise test, pressure drop test and ultrasonic test

- Bubble detection: immersion or application of liquid (method C1, C2 according to DIN EN 1779)

- Vacuum tightness test with helium gas detector (method A3, B2.1 according to DIN EN 1779)

- Fine leak detection with selective gas detectors (method B4 according to DIN EN 1779)

- Tightness tests with vacuum chamber or flexible hood (method B3 according to DIN EN 1779)

- Helium tightness test of components up to 180bar overpressure

Our special offer for refrigeration applications

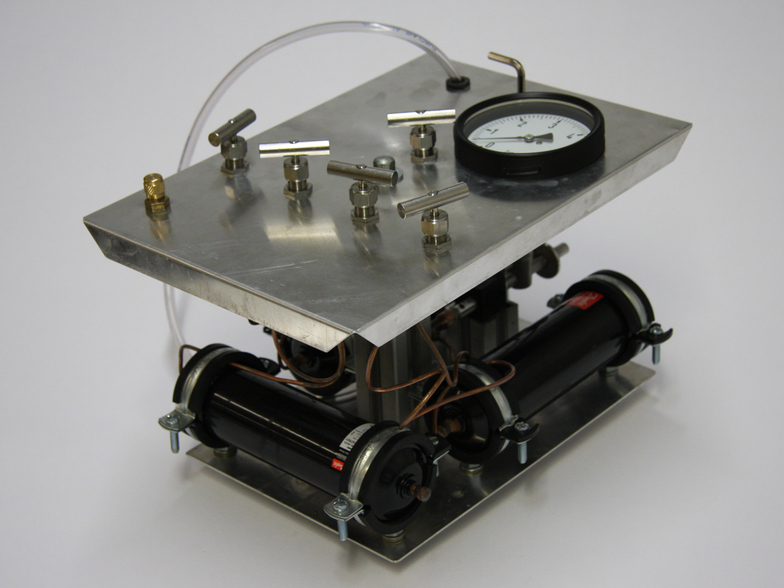

- Construction of customization tightness test benches

- Development and construction of strength test stands and plants for test gas recovery

- Leak detection / tightness test when using HFCs, HFC mixtures, HFO and natural refrigerants such as hydrocarbons, NH3 and CO2

- Leak detection / tightness test with forming gas

- Tightness test with mass spectrometer measurement technique for helium and higher masses

- Lectures and trainings at the ILK or on the spot (also offered in cooperation with the Bundesfachschule Kälte-Klima-Technik Maintal and Niedersachswerfen)

- Support of small trade and industry regarding (regular) tightness tests of refrigeration plants including processing of problems

- Performance tests of mobile leak detectors and room monitoring devices (according to DIN EN 14624)

- Delivery of individual test leaks according to customer requirements

- Qualification of leak tightness of components and connections (according to DIN EN 16084 resp. DIN EN ISO 14903)

Technological basis at the ILK

- State-of-the-art measurement technology. Gas detectors, pressure and temperature measuring instruments, calibration standards

- Mobile testing devices for measurements on the spot

- Tightness test laboratory

- Participation in the special committee for tightness testing of DGZfP

- Longtime experiences from research projects and industry tasks

Your Request

Further Projects - Measurements and Tests

Hydrogen and methane testing field at the ILK

Simultaneously pressures up to 1,000 bar, temperatures down to –253°C