You are here: Home / Measurements and Tests

Verification of storage suitability of cryo tubes

Artificial aging of primary packaging for biobanking applications

During long term storage of biological samples in bio- or cryobanks, cryotubes (also referred to as vials) are often used. This primary packaging is intended to protect valuable samples from contamination and to guarantee the chemical and biological integrity of the sample even after several decades of low temperature storage. The goal of the R&D project is to prove the storage suitability of these tubes by comparative evaluation of characteristic material properties before and after artificial aging.

The following key points should be implemented:

- The impractical real-time test is replaced by thermal cycling, so that the conditions of long-term storage (usually several decades) can be approximated.

- The heating and cooling rates of the thermal cycling test chamber can be set in a defined range to simulate the real-world freezing and thawing processes.

- Detection of aging effects by thermal and mechanical test methods, in particular calorimetric measurements and tensile and compression testing, as well as visualization of the aging effects by microscopic eximination and imaging.

- The methods for leak testing of cryotubes already developed at the ILK (gravimetric leak test, tightness against carbon dioxide while dry ice storage and tightness against liquid nitrogen) are supplemented by a test method for tightness during storage in the gas phase of liquid nitrogen.

As a result a new possibility for accelerated aging of cryotubes is available, which can simulate the material wear by storage processes in cryobanks under laboratory conditions in a short time. By multiple passing through critical temperatures or temperature ranges, the stress of usual storage conditions is simulated in the best possible way. For the evaluation of the storage suitability test methods are established to detect time and temperature dependent changes of material properties and the effects of mechanical and chemical stress on the sealing behavior of the tubes.

In this way, possible damage to the valuable samples through the use of improper packaging material can be prevented or at least reduced by selecting better suited tube materials.

Further Projects - Measurements and Tests

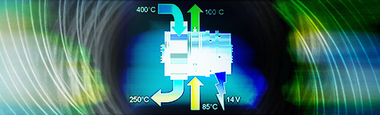

Hydrogen and methane testing field at the ILK

Simultaneously pressures up to 1,000 bar, temperatures down to –253°C