You are here: Home / Research and Development

Certifiable connection types in cryogenics

Detachable and permanent connections, adhesive bond / form closure / force closure

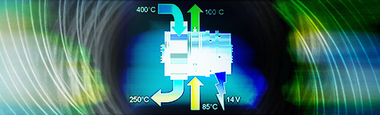

The applications of cryogenic and vacuum technology impose special requirements on connection technologies. To determine the appropriate connections the application parameters such as temperature, vacuum and pressure, leak rate, materials, surface properties, radiation resistance, magnetic permeability etc. should be considered.

Connection technologies even if not being part of a standardized process more often have to be subject of a certification or qualification due to increasing quality requirements, e.g. pressure equipment directive 2014/68/EU. Therefore adequate designing and testing is necessary.

Innovations

The intended innovations relate to complete cryogenic systems considering the process chain from room temperature to low temperature range regarding the respectively required specifications.

- Development of application-related connection technologies with defined requirements and derived mechanical limit values

- Examination of existing connection technologies regarding applicability and further development towards secure and functional technologies

- Evaluation and definition of application limits to aim for a feasible certification and the subsequent conformity with European guidelines

Project objectives

- Application-related examination of various connection technologies

- Further development and adaptation of existing connections to the requirements of cryogenic and vacuum technology

- Examination on composite materials

- Examination on component geometries and their influence on the connection

- Determination of process parameters (e.g. TIG welding, brazing,...)

- Determination of test limit values, especially for test specimens deviating from standards

- Calculation according to common standards, simulation (FEM, ...) and testing

- Realization and certification of selected connection technologies

Further Projects - Research and Development

Electrochemical decontamination of electrically conducting surfaces „EDeKo II“

Improvement of sanitary prevention by electrochemical decontamination