You are here: Home / Research and Development

Hydrogen and methane testing field at the ILK

Simultaneously pressures up to 1,000 bar, temperatures down to –253°C

- Test and qualification of components at temperatures ranging from 20 K (−253 °C) to room temperature and pressures ranging from high vacuum to 1000 bar (e.g. test of sealings, permeation tests).

- Investigation of charge and discharge processes at cryogenic or room-temperature-operated storage systems for hydrogen and methane (e.g. adsorber storage systems, cryo-compressed hydrogen).

- Investigation of catalyst materials for the ortho–para conversion of hydrogen.

- Long-time thermal charging of components and materials in hydrogen or methane atmosphere at up to +200 °C and up to 160 bar for investigating degradation effects (e.g. hydrogen embrittlement).

- Development of different hydrogen and methane components (e.g. recooling systems, latent-heat storage systems, cryogenic pressure storage systems, heat exchangers, cryogenic pumps).

- Realisation of complete-system solutions for hydrogen and methane.

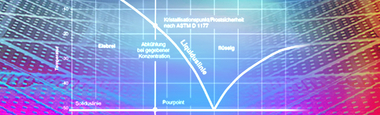

The following diagram depicts the specific storage density that can be achieved depending on temperature and pressure:

Further Projects - Research and Development

Multifunctional electronic modules for cryogenic applications

Electronic with less wiring effort - more than 100 sensors via one feedthrough

Certifiable connection types in cryogenics

Detachable and permanent connections, adhesive bond / form closure / force closure

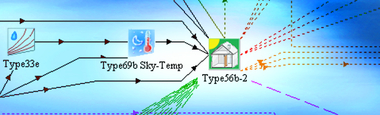

Combined building and system simulation

Scientific analysis of thermodynamic processes in buildings and its systems

Development of test methods and test rigs for stationary integrated refrigeration units

How efficient is my refrigeration unit?