Project aim:

The aim of the project is to further develop of a test method for investigating the swelling and shrinkage behaviour of polymeric materials in flammable fluids (e.g. ethane, propane, iso-butane, hydrogen) under process conditions (p-T). The tests are possible in the gas and liquid phase as well as in supercritical fluids. In particular, O-rings have proved to be useful specimens on which swelling and shrinkage behaviour can be measured under defined conditions, even in a pre-stressed state.

Due to increasing environmental regulations, hydrocarbons, i.e. flammable refrigerants, are increasingly being used today. This is accompanied by increasing safety requirements for the tightness of components and systems. This applies not only to refrigerants, but also to hydrogen, which is set to play a central role in the energy industry.

Elastomeric seals are essential for the leak-free operation of refrigeration systems and for the sealing (static and dynamic seals) of hydrogen-bearing systems. They contribute to the safety, reliability and efficiency of these systems. The correct selection and application of the materials are of crucial importance, as elastomers are only ever suitable for a specific area of application. It is therefore important that the material properties are precisely matched to the requirements of the systems with their wetted parts in order to ensure safe and long-lasting operation.

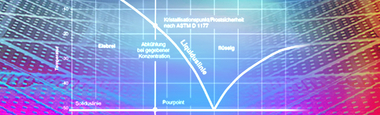

There is therefore a need for test methods that make it possible to determine the various material properties of elastomers in contact with flammable refrigerants and hydrogen. The swelling behaviour of the materials is an important parameter in characterising the resistance and suitability for these media. In general, greater swelling effects occur when there is a chemical similarity between the polymer chain and the acting medium. (e.g. perfluorocarbon elastomer/perfluororoelastomer in contact with fluorinated hydrocarbons).

The test setup is designed to allow testing at temperatures of up to 80 °C and pressures of up to 40 bar. This range of conditions covers most of the operating conditions that occur in real operation with flammable refrigerants. In the case of hydrogen, for example, the maximum pressure encountered in the high-temperature fuel cell application is 30 bar.