You are here: Home / Software Development

Multifunctional electronic modules for cryogenic applications

Electronic with less wiring effort - more than 100 sensors via one feedthrough

The aim of the R&D project was the development of multifunctional electronic modules that enable the operation of a large number and variety of sensors to be used for cryogenic applications.

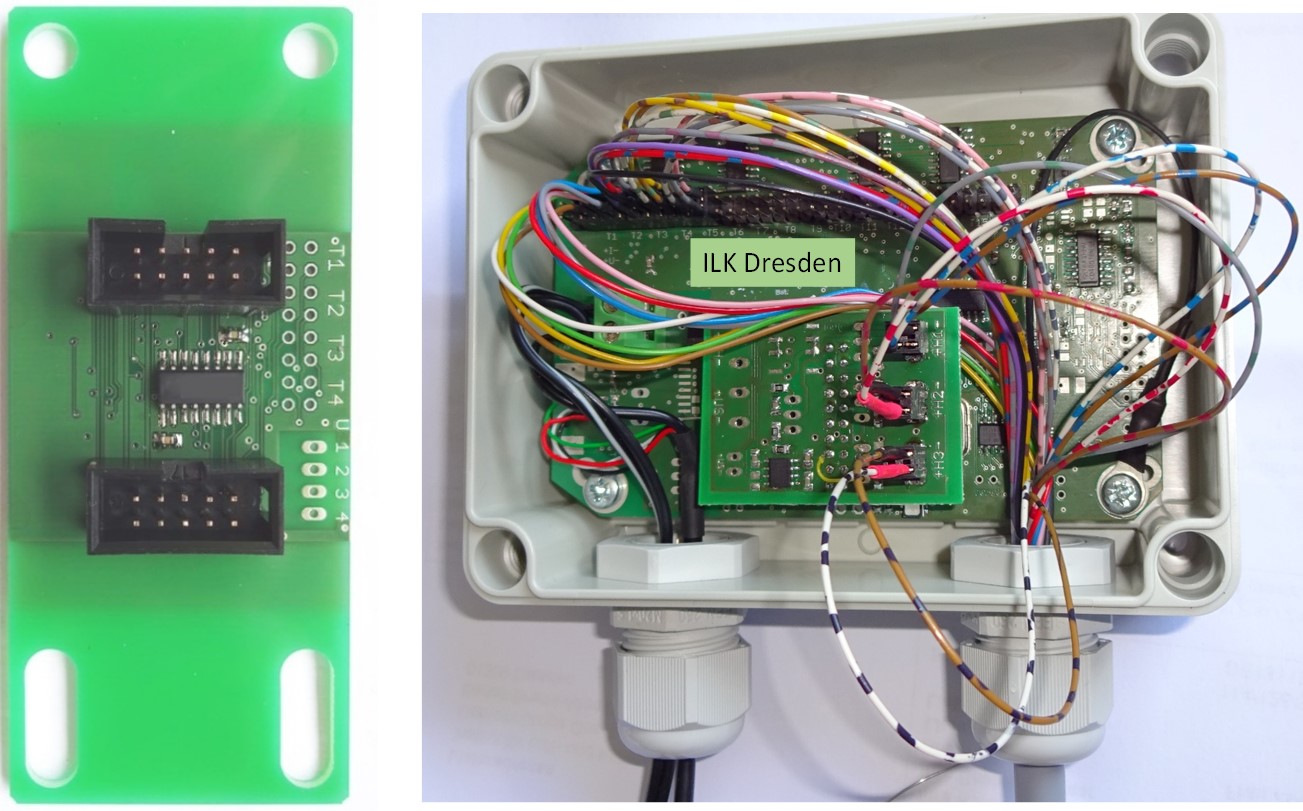

Usually, cryogenic sensors are located in cryostats and all cables have to be decoupled via feedthroughs, which leads to an increased heat input. To avoid this, we have developed and implemented various multiplexers as a part of the project, which work well under cryogenic conditions, see Figure 1 (left). The multiplexers are designed for an operation with a 10-wire bus system with arbitrary expandability. The multiplexers were developed and optimized for minimum interference, maximum function and compactness.

Another major goal of the R&D project was the development of a universal measuring bridge for any sensors, see Figure 1 (right). As a result, different electronic multifunction modules and cold multiplexers were developed, realized and validated. These modules are characterized by the fact that any sensors can be connected by means of a universal circuit board design. The selection of the modules was modular, which is why special components were selected and tested depending on the requirements. Among the options are: Different references (resistance, voltage), amplification factors, active shielding, battery operation, displays (TFT, LCD), interfaces (RS485, USB), storage options (SD card), electrical isolation, interface to multiplexers, and type of housing.

During development, special attention was paid to electromagnetic compatibility and interference sensitivity during switching operations, such as in heater control. The accuracy is determined by reference resistors and voltages. In addition, the time response of the facial expressions was a key parameter of the development in order to ensure a fast and stable measurement.

Within the R&D project a software was programmed which is available as a universal platform for any configuration of modules. The modules can be in-house developments or commercially available products. Each controller supports a freely definable number of sensors, actuators, controllers and binary inputs and outputs. Each sensor, actuator and controller can represent any common physical quantity. These include temperature, pressure, level, voltage, current, resistance etc.

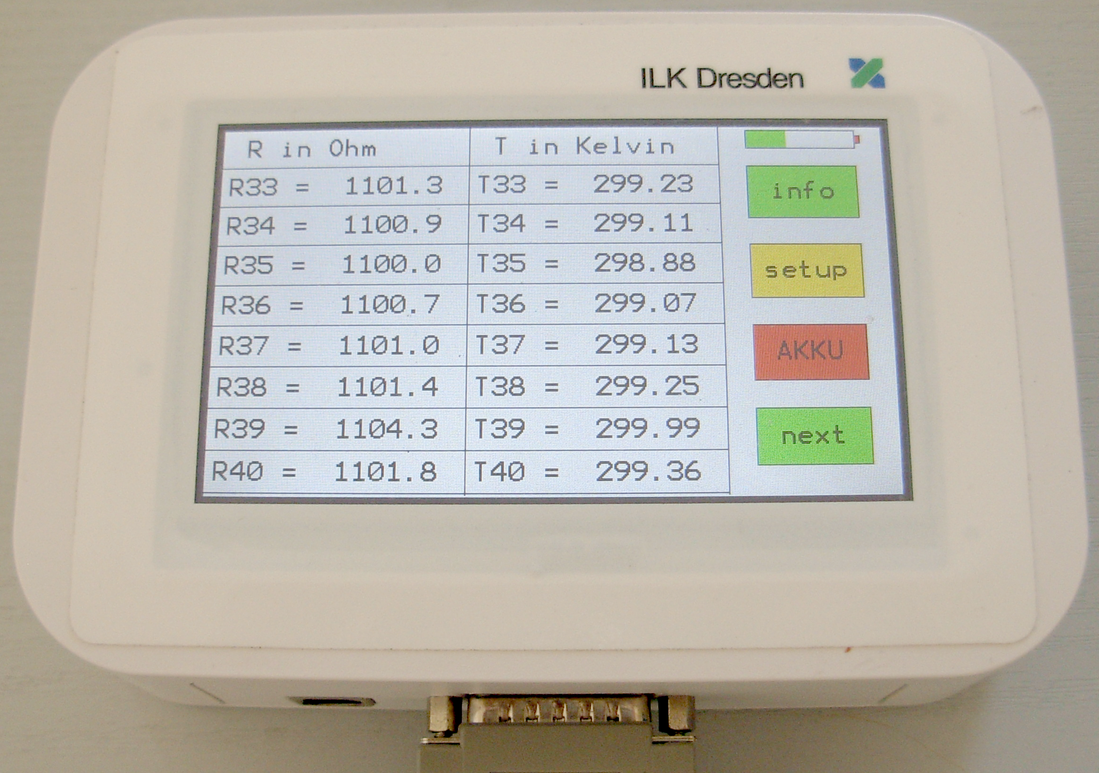

With our development of a universal temperature measuring bridge, any temperature sensors can be read out with high accuracy, see Figure 2.

Further Projects - Software Development

Optimizing HVAC operation with machine learning

Intelligent control of HVAC systems – high comfort with low energy demand

Software for technical building equipment

Design cooling load and energetic annual simulation (VDI 2078, VDI 6007, VDI 6020)